Multifunctional Inspection Robot

Automated巡检 for safety-critical environments, built to reduce manual rounds, improve detection consistency, and deliver actionable alarms with video, sensor, and event traceability.

Automated巡检 for safety-critical environments, built to reduce manual rounds, improve detection consistency, and deliver actionable alarms with video, sensor, and event traceability.

Intelligent inspection is not only about collecting data. It is about protecting the life-safety baseline of a site by visiting the right locations, at the right frequency, with consistent sensing and clear records.

The Multifunctional Inspection Robot supports data-driven management: routine readings, historical analysis, and early warning workflows that help teams move from reactive response to proactive prevention. The result is fewer blind spots, better incident evidence, and reduced labor cost for repetitive rounds.

Designed for safety-driven facilities where consistent inspection matters more than occasional checks.

Designed for safety-driven facilities where consistent inspection matters more than occasional checks.

From equipment rooms to public infrastructure, the robot adapts to structured patrol routes and repeatable tasks.

Cabinet temperature checks, indicator light status, smoke and flame sensing, and leak detection around critical racks.

Instrument reading, switch/breaker status recognition, noise and gas monitoring, and temperature/humidity tracking.

Blind-spot inspection, safety passage occupancy checks, PPE compliance recognition, and vibration/noise monitoring.

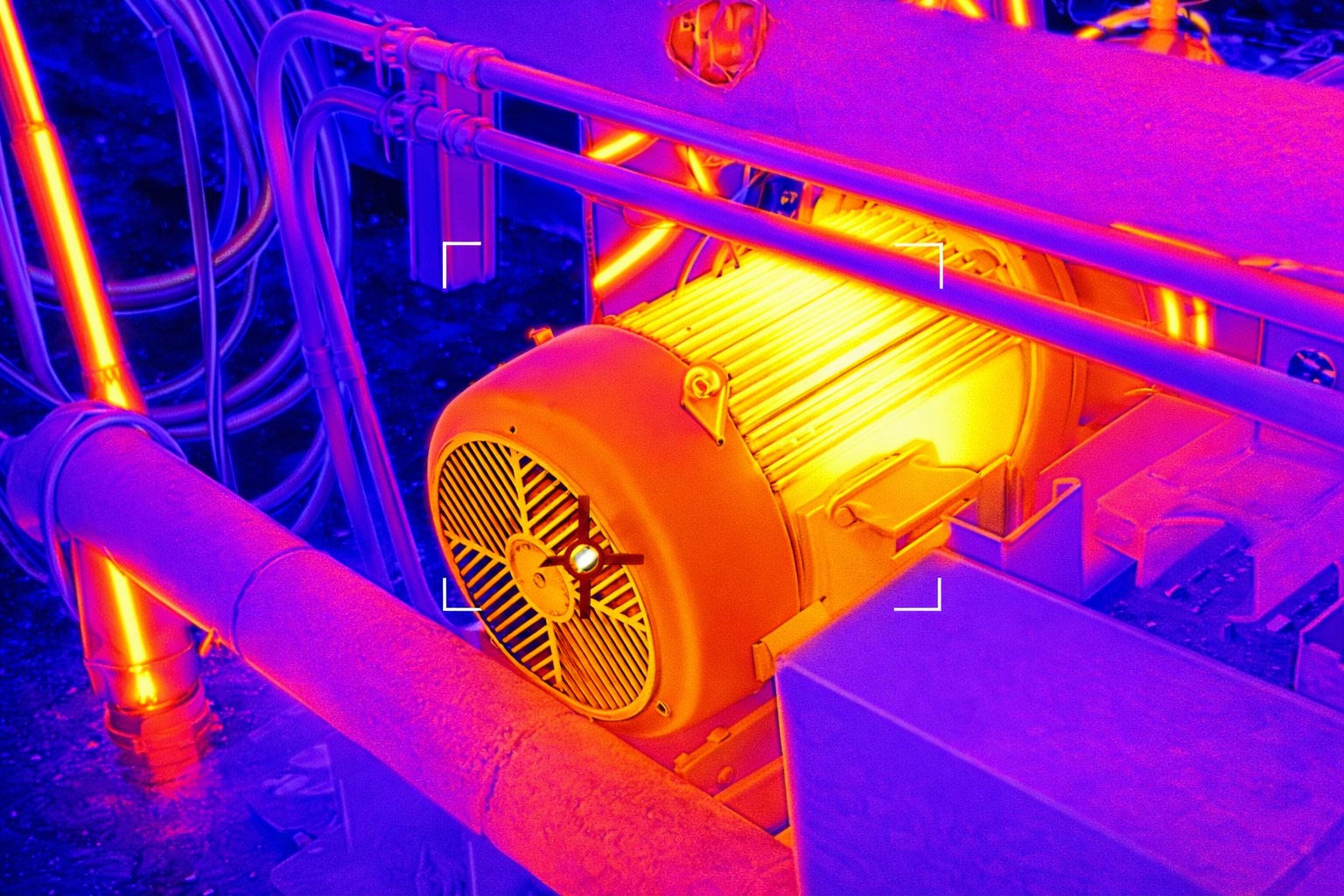

Thermal imaging (optional), gas detection, pipeline/valve status checks, and early warning for smoke or flame events.

Night inspections, environmental sensing, emergency route checks, and abnormal event reporting across large halls.

Intrusion detection, door/window status checks, blocked corridor recognition, and visible deterrence patrols.

Hazard zone checks, disorder stacking detection, smoke/flame sensing, and routine verification of safety assets.

Temperature/humidity and smoke monitoring, access control support, and safer late-hour patrol routines.

The platform combines core environmental detection with safety-asset verification. Each item can trigger alarms, log events, and support escalation workflows, turning routine patrols into a structured safety system.

Continuous sensing helps identify overheating, corrosion risks, and unstable workshop conditions.

Early detection for smoldering events, faster intervention, and reduced secondary losses.

Wide-angle fire recognition supports rapid warning and coordinated response in open areas.

Detect blocked evacuation routes and recurring violations to reduce risk during real emergencies.

Identify failed guidance lights and improve evacuation readiness before incidents happen.

Recognize extinguishers that are blocked, missing, or poorly placed, helping teams keep access clear.

Verify hydrant locations remain unobstructed, supporting the critical first minutes of firefighting.

Visual temperature sensing for equipment surfaces, distribution patterns, and fault detection support.

Optional thermal imaging adds visible temperature sensing for equipment and high-risk zones.

Optional thermal imaging adds visible temperature sensing for equipment and high-risk zones.

Secondary development support enables custom tasks, recognition logic, and additional sensors.

A practical inspection robot must be stable, safe, and serviceable. The platform combines navigation sensors, safety sensors, and clear on-device signaling so that it can operate in mixed environments with people and equipment.

Laser radar + ultrasonic radar support navigation, positioning, and obstacle avoidance.

High-definition camera and rotating gimbal support route verification and abnormal event capture.

Warning light and sound alarm help on-site staff notice and respond quickly when needed.

Sensor packages and lift/elevator options can be selected based on site layout.

Sensor packages and lift/elevator options can be selected based on site layout.

Key parameters for planning deployments, corridors, and charging operations.